VSI Series Impact Crusher: An Efficient Solution for Sand Making and Crushing

Release time:

2025/06/20

Source:

网站

As infrastructure projects such as construction, highways, and water conservancy continue to advance, the demand for manufactured sand is rapidly increasing. To meet the need for high-quality aggregates, selecting an efficient and stable sand-making machine has become essential. The Leimeng VSI Series Impact Crusher is widely used in this context, delivering outstanding performance in improving sand output and optimizing particle shape. It has become a key piece of equipment in many manufactured sand production lines.

1. Applications of VSI Series in Manufactured Sand Production

With the depletion of natural sand resources, the demand for manufactured sand in infrastructure development has surged. The VSI series impact crusher has emerged as a core component in manufactured sand production lines. This equipment accelerates material through a high-speed rotating rotor, projecting it against the crushing chamber wall or anvil plates to achieve "rock-on-rock" or "rock-on-iron" crushing. The result is high-quality artificial sand with excellent shape and well-graded particles.

Leimeng's VSI impact crushers are compatible with a wide range of raw materials, including granite, basalt, limestone, cement clinker, quartz, and iron ore. They are extensively used in aggregate processing, pre-cement crushing, refractory material handling, and in high-grade construction projects such as highways, railways, and airports.

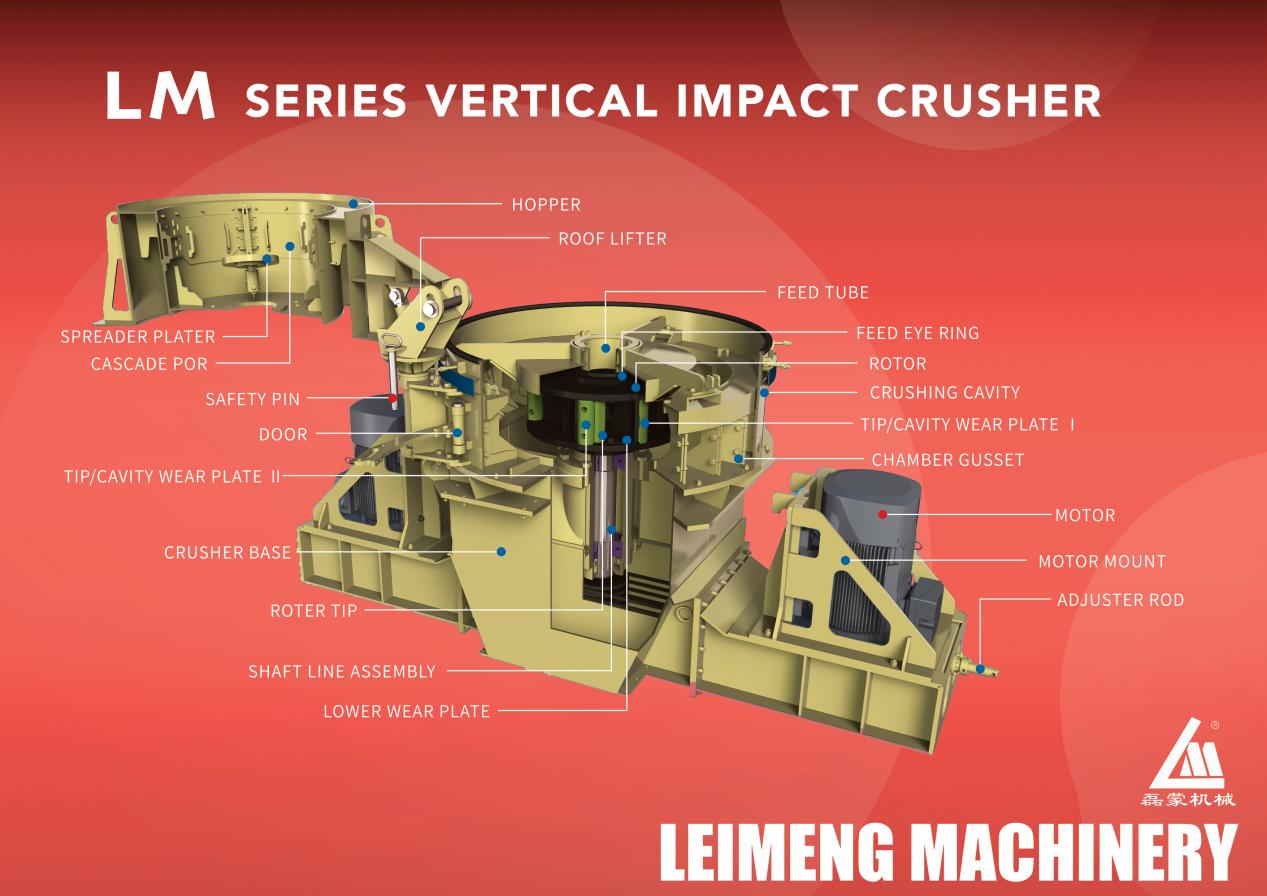

2. Key Structure and Working Principle

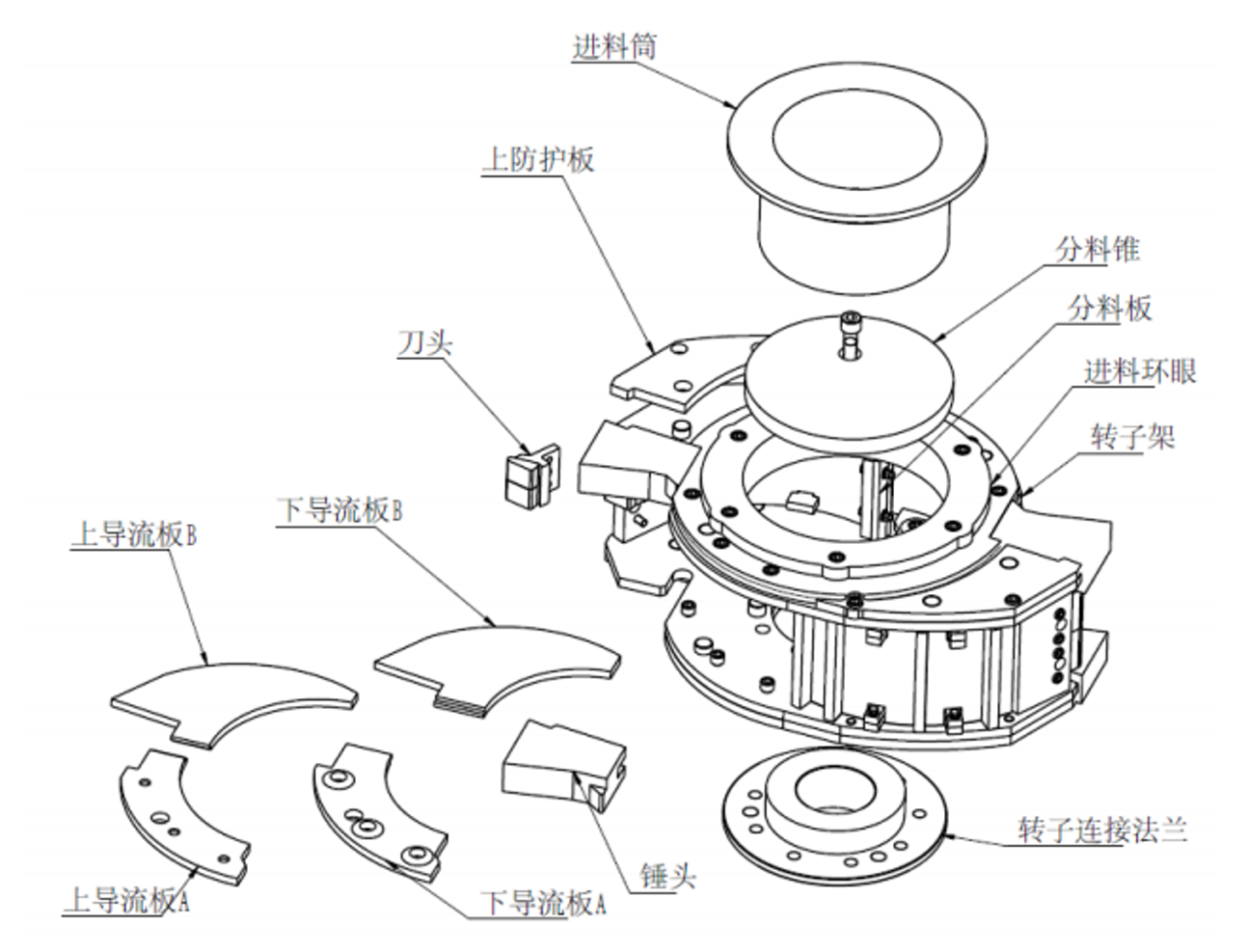

Leimeng’s VSI series features a vertical shaft structure with critical components including:

- Rotor chamber

- Feed hopper and distributor

- Peripheral anvils or impact plates

- Main shaft and motor system

- Adjustable discharge port

Working Principle:

Materials are fed vertically from the top inlet. After acceleration within the rotor, they are propelled at high speeds into the chamber, colliding with the liners or anvil plates. The process involves high-speed impact and inter-material crushing. This mechanism of “high-speed rotation + multiple impact points” enables fine crushing and shaping, resulting in high-quality sand output.

The rotor chamber, considered the heart of the impact crusher, plays a decisive role in material acceleration, energy conversion, and crushing efficiency.

3. Dual-Chamber Rotor Design: Balancing Efficiency and Energy Consumption

A major innovation in the Leimeng VSI series is its dual-chamber rotor design, an upgrade from the traditional single-chamber rotor. It offers the following advantages:

Increased Throwing Area:

The dual-chamber design expands the rotor’s internal space, enabling greater acceleration of materials per unit time. This increases throwing velocity and crushing energy, significantly improving output capacity.

Optimized Material Flow:

The structure prevents material build-up or secondary friction, reducing energy loss. It also ensures uniform material distribution and focused throwing angles, boosting crushing efficiency and shape control.

Multiple Crushing Modes:

Depending on the application, users can switch between "rock-on-rock" or "rock-on-iron" modes. The former is ideal for high-quality sand production, while the latter suits harder ores—providing true versatility from a single machine.

4. Flexible Model Selection: Catering to Various Materials and Capacity Needs

The Leimeng VSI series offers multiple models, with a maximum capacity of 550 tons per hour. It supports feed sizes up to 60 mm, and the discharge size can be adjusted to meet specific grading requirements, accommodating coarse, medium, and fine sand production.

|

Parameter |

Range/Specification |

|

Max feed size |

≤ 60 mm |

|

Discharge size |

Adjustable for various grading needs |

|

Motor power |

250–315 kW × 2 (varies by model) |

|

Suitable materials |

Granite, basalt, quartz, cement clinker, etc. |

|

Max capacity |

550 TPH (depending on material characteristics) |

How to Select the Right Model?

- For high-hardness ores (e.g., quartz, iron ore), choose the rock-on-iron mode for higher crushing efficiency.

- For construction-grade sand (e.g., limestone, basalt), the rock-on-rock mode is recommended for better particle shape.

- For high-capacity, continuous operation, opt for models with higher power and larger rotors.

5. Leimeng Brand Advantages

Choosing the Leimeng VSI series impact crusher means more than just buying a machine—it's about investing in a stable, efficient, and economical crushing solution.

Key Technical Advantages:

- Optimized Wear Parts:

We have improved and redesigned the key components of the machine to increase working efficiency and service life.

- Traditional impeller and liner are one piece; ours are divided into two interchangeable parts, extending service life by 40%.

- Conventional VSI uses square impact blocks; ours feature diamond-shaped blocks to prevent direct wear and extend lifespan by 30%.

- Deeper rotor chambers increase processing capacity.

- Dual motors ensure optimal power and speed balance.

- Easy Maintenance:

Key components use international brands for durability and easy servicing.

- Light oil lubrication control system auto-adjusts oil feed based on machine condition, reducing labor costs. The efficient cooling system keeps operating temperature around 25°C, protecting bearings and motors and reducing friction.

- Hydraulic top-opening system (imported from Japan) allows one-person operation for rotor or part replacement—minimizing downtime.

- Traditional feeding uses a fixed cone that must be removed to change feed mode; our adjustable distributor plate allows fast switching between central and cascading feed, improving efficiency.

- Smart Control and High Stability:

Utilizing top-brand materials and motors to enhance equipment stability and intelligence level.

- Core parts made with top-grade alloy materials.

- Bearings from Timken, NSK, or other leading brands.

- Siemens motors with IP54/55 protection available for superior performance.

Our Services Include:

- Professional model selection and application consultation

- Installation, commissioning, and operator training

- Spare parts supply and after-sales service

- Fast delivery and global technical support

Conclusion

As manufactured sand increasingly replaces natural sand in construction, selecting a high-performance, adaptable crushing machine is more critical than ever. The Leimeng VSI Series Vertical Shaft Impact Crusher is an ideal solution, combining sand-making capacity, energy efficiency, and flexible application.

Whether you are building a new sand production line or upgrading an existing one, Leimeng offers customized, one-stop crushing solutions to help you stand out in a competitive market.

To receive product specification sheets, configuration advice, or a quotation, feel free to contact the Leimeng engineering team. We’re here to provide expert support and personalized service.

Key words: