In-Depth Analysis of the Working Principle of DH/DS Single-Cylinder Cone Crushers

Release time:

2025/06/09

Source:

网站

In the mining and aggregate industries, crushing equipment is essential for achieving efficient production. Among them, the single-cylinder hydraulic cone crusher stands out for its simple structure, ease of operation, and low maintenance costs, making it widely used in secondary and fine crushing applications. Particularly in secondary crushing, it plays a central role. The DH/DS series single-cylinder hydraulic cone crushers from Leimeng have become a preferred choice among industry users due to their outstanding performance and reliability. This article provides a detailed analysis of the working principle of the DH/DS series and compares it with the internationally renowned Sandvik CS series, highlighting their technical similarities and application advantages.

Application of Single-Cylinder Hydraulic Cone Crushers in the Mining and Aggregate Industries

Single-cylinder hydraulic cone crushers are widely used in mining, sand and gravel aggregates, construction, road building, and concrete batching plants due to their compact structure, high degree of automation, and stable operation. In secondary crushing, they efficiently reduce the size of materials from primary crushers to meet required particle sizes, providing high-quality feed for subsequent fine crushing or sand-making processes. Their high crushing efficiency and excellent particle shape make them indispensable components of modern crushing production lines.

Structural and Functional Comparison Between DH/DS Series and Sandvik CS Series

Leimeng's DH/DS series single-cylinder hydraulic cone crushers are designed based on advanced international crushing equipment technology and share high structural and functional consistency with the world-renowned Sandvik CS series. This design not only reflects the technological advancement of domestic crushing equipment but also offers users a cost-effective and reliable option.

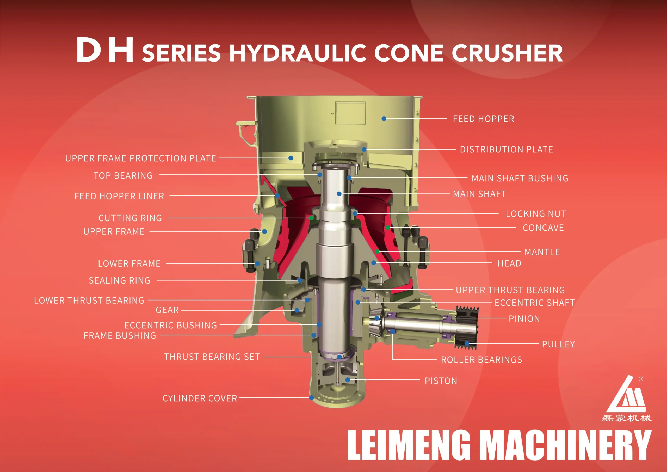

In terms of structure, the DH/DS series mirrors the CS series in key components such as the main shaft, moving cone, fixed cone, and hydraulic system layout. The machines are manufactured using integral casting or high-strength alloy materials, resulting in a compact structure with strong rigidity and excellent impact resistance. They are well-suited to harsh operating environments and heavy-duty applications. Additionally, detailed engineering in areas like the connection between the moving cone and main shaft, support structure, and eccentric mechanism further ensures stable and reliable operation.

Both series utilize advanced hydraulic control systems to manage the lifting movement of the main shaft, enabling overload protection and flexible adjustment of the discharge opening. When uncrushable materials (e.g., iron blocks, rebar) accidentally enter the crushing chamber, the hydraulic system quickly reacts by releasing pressure, allowing the main shaft to descend instantly and preventing damage from excessive force. This mechanism not only extends equipment life but also ensures continuous and safe operation.

Under normal conditions, the hydraulic system also allows precise adjustment of the discharge opening based on different material requirements, ensuring consistent product particle size and improving controllability and quality.

Interchangeability of Key Components and Maintenance Advantages

The DH/DS series offers high interchangeability of key parts with the Sandvik CS series, covering components such as moving cones, fixed cone liners, hydraulic cylinder seals, and main shafts. These parts can be directly replaced without the need to modify installation interfaces or structures, providing users with practical and economic benefits.

First, this interchangeability reduces the pressure on spare parts inventory. Traditionally, to ensure uninterrupted production, users must stock a wide range of parts for different brands and models—resulting in significant storage and cost burdens. With Leimeng’s DH/DS series, users who also own CS series equipment can utilize domestically produced parts, streamline inventory management, and improve supply chain flexibility and responsiveness.

Second, the compatibility of parts directly enhances maintenance efficiency. At production sites, unexpected parts replacement is common, and the availability and speed of part replacement are crucial to minimizing downtime. Thanks to component compatibility, users can opt for cost-effective domestic replacements in the event of a breakdown, avoiding long delays associated with sourcing imported parts and ensuring continuous production.

More importantly, domestic parts offer a significant price advantage. Compared with expensive and slow-to-arrive original imported parts, Leimeng’s accessories are more affordable, with shorter delivery times and faster service response. This substantially reduces operating costs over the equipment’s lifecycle. For large and medium-sized mining operations or aggregate plants with multiple production lines, this “same quality, lower cost” maintenance model yields considerable economic returns.

Application Advantages of Single-Cylinder Hydraulic Cone Crushers

The single-cylinder hydraulic cone crusher offers several significant advantages in secondary crushing:

- High Capacity: An optimized crushing chamber and efficient transmission system enable high throughput, meeting the needs of large-scale production.

- Excellent Particle Shape: By using lamination crushing principles, materials are compressed multiple times in the chamber, resulting in uniform and well-graded products suitable for high-quality aggregate applications.

- High Automation: Equipped with advanced automatic control systems, these crushers monitor real-time operating status and automatically adjust the discharge opening for optimal performance.

- Stable Operation: With a well-designed structure and critical parts made from high-strength materials, these crushers run smoothly with low failure rates and are easy to maintain.

Differences Between DS and DH Models and Their Combined Application

Leimeng’s DS and DH models are designed with different crushing chamber types to meet diverse production requirements:

- DS Model: Features a standard crushing chamber, ideal for general secondary crushing with moderate discharge size. It is suitable for most aggregate production lines.

- DH Model: Equipped with a fine crushing chamber, this model produces finer output, making it ideal for pre-sand making operations where fine material is required.

In practical applications, users can combine DS and DH models based on the specific needs of their production lines, enabling continuous crushing from secondary to fine stages. This enhances both the flexibility and efficiency of the crushing process.

Conclusion: Advantages and Prospects of the DH/DS Series

Leimeng’s DH/DS series single-cylinder hydraulic cone crushers feature highly consistent structural design, performance, and component compatibility with the Sandvik CS series, offering a mature and reliable technological foundation. They perform excellently in real-world applications and cater to a wide range of crushing scenarios, especially in secondary crushing roles. Furthermore, domestic equipment offers clear advantages in cost control and parts supply, providing users with a high-value alternative.

As the demand for efficient, eco-friendly, and intelligent equipment continues to grow in the mining and aggregate industries, the DH/DS series—backed by excellent performance and dependable quality—is poised to take on a more prominent role in the market of the future.

Key words: